SF-2100C 2-Axis CNC Controller CNC Flame/ Plasma Cutting Machine Plasma Cutter

A:link {color: #C81269; text-decoration:underline;} A:visited {color: #666666; text-decoration:underline;} A:hover {color: #333333; text-decoration:underline;} A:active {color: #C81269; text-decoration:underline;}. Content {font-family: Verdana, Arial, helvetica, sans-serif; font-size: 11px; font-style: normal; font-weight: normal; color: #000000; line-height: 18px; text-decoration:none; text-align: justify;}.

Submenu{font-family: Verdana, Arial, helvetica, sans-serif; font-size: 11px; font-style: normal; font-weight: bold; color: #666666; line-height: 15px; left: 20px; margin-left: 20px; text-decoration:none;}. Content_white {font-family: Verdana, Arial, helvetica, sans-serif; font-size: 11px; font-style: normal; font-weight: normal; color: #FFFFFF; line-height: 16px; text-decoration:none; text-align: justify;}. Best_seller {font-family: Verdana, Arial, Helvetica, sans-serif; font-size: 12px; font-style: normal; font-weight: normal; color: #000000; text-decoration:none; text-align: left; padding: 0px;}.

Best_seller_even {font-family: Verdana, Arial, helvetica, sans-serif; font-size: 12px; font-style: normal; font-weight: normal; color: #000000; line-height: 14px; text-decoration:none; text-align: left; padding-top: 10px; padding-right: 0px; padding-bottom: 0px; padding-left: 0px; background-color: #EBEBEB;}. Small {font-family: Verdana, Arial, Helvetica, sans-serif; font-size: 9px; font-style: normal; font-weight: normal; color: #000000; line-height: 18px; text-decoration:none; text-align: justify;}.SF-2100C 2-Axis CNC Controller CNC Flame/ Plasma Cutting Machine Plasma Cutter. Brief introduction: Note: The USB port output power of the system is very small, and it can only be used by the U disk. It cannot be connected to other USB devices to prevent damage. System functions: SF-2100C-QG cutting machine CNC system is suitable for all kinds of flame / plasma, high pressure water jet, laser cutting machine, widely used in metal processing, advertising, stone and other industries. The system is highly reliable and has the ability to resist plasma interference, lightning strikes and surges.

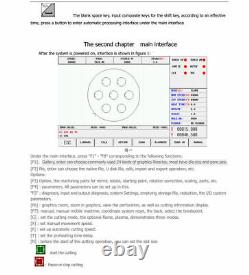

Practical flame/plasma cutting process, automatic corner rotation control and height control control during plasma processing; remote operation with wireless remote control. It has the function of kerf compensation, and whether the compensation in the program is reasonable, and the corresponding report is made for the user to choose; Breakpoint recovery, automatic power-off recovery function, automatic memory breakpoints; Arbitrary selection and selection of perforation point processing functions; It has an epitaxial perforation function for thick plates and a bridging function for thin plates; Back-off, selection, breakpoint recovery, optional perforation position and other functions, greatly facilitate the user's control; Transfer cutting at any time; It adopts a special small line segment processing function, which makes it easy to walk and can be widely used in metal cutting and advertising, wrought iron, etc. A library of 24 graphics (expandable and customizable) containing common basic machining parts; Fully compatible with StarCAM nesting software, compatible with IBE (Germany), FASTCAM and other mainstream nesting software; Chinese and English operation interface conversion, dynamic graphic display, 1 to 8 times of graphic magnification, automatic tracking of moving points, U disk reading program and timely software upgrade.

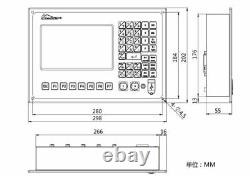

Specification: Technical indicators: Processor: using industrial grade ARM processing chip; Display: 7-inch color LCD display; Power. Input\Output: The system provides 16 optically isolated inputs and 16 optically isolated outputs. Number of linkage axes: 2 axes, (can be driven by X-axis bilaterally or Y-axis bilaterally) Maximum speed: not less than 24 m / min; Pulse equivalent: flexible adjustment; Storage space: 4G large user program storage capacity, processing procedures are not limited; Chassis size: 298 × 202 × 65 (mm); Working temperature: 0 ° C +40 ° C; storage temperature : -40 ° C +60 ° C ; Function word definition: N command segment number G preparation function M auxiliary function T tool function (in this system is the flame width) L cycle number, delay time X X axis (diameter) absolute coordinates Y Y axis absolute coordinates I When the arc is machined, the center coordinate value is reduced by the X axis starting point value. When the arc is machined, the center coordinate value is reduced by the Y axis starting point value.

R arc radius specification H arc string height specification A auxiliary variable F machining speed specification for G01, G02, G03 Parameter Description: Speed?? parameter Starting speed, adjustment time and maximum speed limit of each axis; System parameters Electronic gear ratio of each axis, machine origin, reference point, backlash, line offset, soft positive/negative limit; Flame cutting parameters Ignition delay, preheating delay, cutting gun up/down delay, perforating torch up/down, piercing delay, etc. Plasma parameter Cutting gun positioning delay, M command for arcing, M command for arc breaking, arc pressure detection selection, positioning detection selection, piercing delay; control parameter Flame/plasma selection, processing speed limit, edge perforation selection, metric/imperial selection, etc. Storage function The modified parameters are stored in the parameter area.

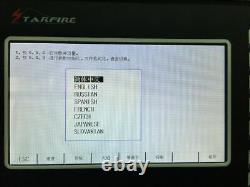

Press the S key continuously to select the external manual control button to select whether it is valid or invalid. Software upgrade operation instructions (software free upgrade) First, the operation steps 1. Format the USB flash drive in FAT or FAT32 format. It is recommended to use the FAT format. Copy the upgrade file into the USB flash drive. The name of the upgrade file must be STARTCNC. Press and hold the arrow button on the left side of the USB port to power on the system, power up the system, and plug the USB disk into the USB port of the system. The system automatically enters the upgrade interface, press the F1 button on the panel (ie, the corresponding button for the upgrade); 5. If the upgrade is normal, after the upgrade is complete, the system will display Upgrade Successful! Turn off the power, pull out the USB flash drive, and the upgrade process is complete. Second, the exception process of the upgrade process Check that the name of the upgrade file must be STARTCNC. If this factor has been eliminated, you can re-operate according to the operation steps. If multiple attempts still fail, you can call customer service. The details of the CNC system are as follows: 1pcs SF-2100C system 1pcs 25 core hole input plug (including sheath) 1pcs 25-pin needle output plug (with sheath) 1pcs 15 core hole remote control plug (including sheath) 1pcs 15-pin pin motor plug (with sheath) 1pcs 9 core hole communication plug (including sheath) 1pcs 3P green terminal DC24V power plug Packing box size: length 400mm\width 220mm\height 340mm; Interface display language. Chinese, English, Russian, French, Spanish, Slovak. 1 x Set of SF-2100C CNC Control System. Unused/unopened merchandise will be fully credited.All emails will be answered within 24 hours.