- Index

- Brand

- Item Type

- Air Cutting Torch (6)

- Cnc Control System (4)

- Cnc Machine Torch (3)

- Cnc Plasma Cutter (3)

- Cut / Tig / Mma (2)

- Cut Welding Machine (3)

- Cutting Torch (8)

- Inverter Welder (43)

- Machine Torch (5)

- Mig Welder (97)

- Plasma Body (5)

- Plasma Cutter (1508)

- Plasma Cutter Nozzle (3)

- Plasma Cutter Tip (8)

- Plasma Cutter Torch (14)

- Plasma Machine Torch (6)

- Plasma Table (5)

- Regular (24)

- Tig / Arc Welder (2)

- Welding Torch Set (71)

- Other (1665)

- Model

- Voltage

- Welded Material

- Welding Process

Plasma Cutter Machine Metal Cutting Machine 55A 17mm 230V Digital Display

Expert customer service in 9 languages. Plasma Cutter - 55 A - 230 V - 17 mm.

Cutting current: 10 - 55 A. Cutting capacity up to 17 mm. Cutting kerf width: 1 mm.

Impressive performance values: 55 amps at 60 percent duty cycle. Cut metallic materials up to 17 millimetres thick. Generous 5 metre-long plasma hose. Performance control thanks to clear LED displays. Do you have a question? The S-Plasma 55H plasma cutter from Stamos Selection convinces with its balanced technical basic parameters and its ease of use. The plasma cutter works cost-effectively and straightforwardly with compressed air and is the ideal helper for all metal work in automotive workshops and in commercial and industrial businesses.It also provides active support to do-it-yourselfers in their private repairs and renovations. The plasma cutter is the ideal tool for cutting all types of metals. S-Plasma-55Hgentle on the material thanks to subsequent cooling The compactly-built plasma cutter from Stamos Selection weighs less than 10 kg, making it an attractive option for mobile use. With an operating voltage of 230 volts, the power unit provides a variable cutting current.

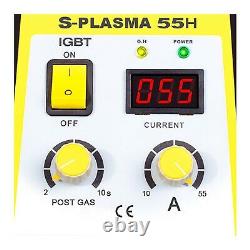

In the range between 10 and. S-Plasma-55H-gentle on the material thanks to subsequent cooling. The compactly-built plasma cutter from Stamos Selection weighs less than 10 kg, making it an attractive option for mobile use. In the range between 10 and 55 amps, the cutting current can be infinitely adjusted to the specific requirements of each individual application. The cutter has some power reserves, which are sufficient for cuts in metal up to 17 millimetres thick. You can cut ordinary tool steel as well as high-alloy special steels. The S-Plasma-55H also makes short work of non-ferrous metals like aluminium, copper and titanium. The issue of material waste can practically be ignored thanks to the cutting width of just one millimetre. The 5 metre long plasma hose in connection with the 4 metre long compressed air supply line ensures sufficient freedom of movement during work. The plasma torch comes with comprehensive accessories, including a pressure reducer with manometer for checking the compressed air values. To prevent undesirable deformations or chemical reactions at the edges after the cutting process is completed, the compressed air continues to flow for a defined interval. On the power unit, the post-flow time can be conveniently set between 2 and 10 seconds by means of a controller.In addition to the post-flow time, the cutting current can also be infinitely adjusted on the power unit. You can check the values on the easy-to-read LED display on the front. Another indicator light signals overheating or other malfunctions. To prevent overheating and the associated possible consequential damage, the base unit is equipped with a powerful air cooling system. If, in the worst case, the appliance still heats up excessively, the overheat protection will take effect.

Another product feature designed for robustness and durability is the resilient housing made of coated steel sheet. The compact design and light weight of less than 10 kg make it possible to use the plasma cutter even in hard-to-reach areas with limited space.

You can carry this powerful electrical device by a sturdy metal handle. Allow yourself to be convinced by high quality and excellent service-order plasma cutter from Stamos Selections today! Cutting current at 100% duty cycle. Cutting current at 60% duty cycle. Cutting depth for high-quality cuts.

44,00 x 31,00 x 17,00 cm. 52 x 38 x 38 cm. IGBT = insulated-gate bipolar transistor. IGBT is a bipolar transistor with an insulated gate electrode. This semi-conducting device is being increasingly used in power electronics because it combines the advantages of two transistor types: the easy controls of the field effect transistor and the fast switching and high breakdown voltage of the bipolar transistor. The IGBT also offers some robustness against short circuits because it limits the electrical continuity.IGBTs are a further development of MOSFET technology. Powerful fans ensure an optimal removal of heat from the unit. For plasma cutting, a gas is required with which the molten metal is blown away from the work surface. Compressed air is a common solution for this. For this purpose, the plasma cutter has a compressor connection.

On the back of every welding machine is a screw with an earthing mark. Before use, earth the unit via a cross-section cable, which must be at least 6 mm². This device works with a 1-phase connection (230 V +/- 10 %). The time after the weld is finished in which gas continues to flow from the torch; this cools the burner and protects the weld from oxidation.

Start the weld by placing pressure on the torch button. Stop the process by releasing the button.

The plasma arc melts the metal and the kinetic energy of the compressed air blows the metal aside. Shows the welding / cutting parameters. The LED light indicates overheating or a malfunction. Shows the value of compressed air the compressor delivers to the plasma cutter. The plasma cutter has a pressure reducing valve which regulates the air pressure. Plasma cable assembly with torch: 4 m. Ceramic cap and swirl ring for plasma. Pressure gauge and pressure regulator. The Stamos Welding Group offers you a variety of different and modern welding devices at extremely low prices. No matter if plasma cutters, combined devices, MIG MAG, TIG or E-Hand welders - products by the Stamos Welding Group are made for daily continuous operation and live up to every expectation. The Stamos Welding Group lays much emphasis on development and improvement of the product range. We are proud to use exclusively the best materials in our machines. Go for the brand products by the Stamos Welding Group and weld like professionals! The item "Plasma Cutter Machine Metal Cutting Machine 55A 17mm 230V Digital Display" is in sale since Friday, May 29, 2020. This item is in the category "Business, Office & Industrial\CNC, Metalworking & Manufacturing\Welding & Soldering Equipment\Welding Equipment & Accessories\Welders, Cutters & Torches\Plasma Cutters".kingdom" and is located in Berlin. This item can be shipped to United Kingdom, Ireland.- Brand: Stamos Welding

- MPN: S-PLASMA 55H

- EAN: 4260223024245

- Shipping weight: 13.300 kg

- Shipping dimension (LxWxH): 52.000 x 38.000 x 38.000 cm

- Weight: 9.4 kg

- Dimension (LxWxH): 44 x 31 x 17 cm

- Model: S-Plasma 55H

- Input voltage: 230V, 1-Phase

- Frequency: 50/60 Hz

- Input current: 16 A

- Open circuit voltage: 104 V

- Degree of housing protection: IP20S

- Insulation class: F

- Overheating protection: Yes

- Cooling: Fan

- Magnetic valve: Yes

- Turn-on duration ED at max. A: 60%

- Cutting current: 10-55 A

- Ignition: Contact

- Cutting depth: 16 mm

- Cutting width: 1 mm

- Compressor connection: 4.5 bar, 30-1001 l/min.

- Security: Yes

- Item Type: Plasma Cutter