- Index

- Brand

- Item Type

- Air Cutting Torch (6)

- Cnc Control System (4)

- Cnc Machine Torch (3)

- Cnc Plasma Cutter (3)

- Cut / Tig / Mma (2)

- Cut Welding Machine (3)

- Cutting Torch (8)

- Inverter Welder (43)

- Machine Torch (5)

- Mig Welder (95)

- Plasma Body (5)

- Plasma Cutter (1508)

- Plasma Cutter Nozzle (3)

- Plasma Cutter Tip (8)

- Plasma Cutter Torch (14)

- Plasma Machine Torch (6)

- Plasma Table (5)

- Regular (24)

- Tig / Arc Welder (2)

- Welding Torch Set (71)

- Other (1665)

- Item Weight

- Model

- Sound

- Voltage

2-Axis SF-2100C CNC controller CNC Plasma Laser Cutting Machine parts System

2-Axis SF-2100C CNC controller CNC Plasma Laser Cutting Machine parts System. Before using the system, please read this handbook thoroughly.

Please inspect the system once it has been opened to see whether it has been damaged during transit. The packing list's contents correspond to the contents of the box. This handbook applies to the CNC system of Beijing Star Peak Control Technology Co.

Please double-check the grid voltage. To guarantee dependable system functioning and worker safety, an AC220V isolation transformer is utilized between the grid and the system. The numerical control system requires a temperature range of 0°C to +40°C in the working environment, with a relative humidity of 0-85%. Working in settings with high temperatures, high humidity, and corrosive gases necessitates extra precautions. Each component of the CNC system should be properly wired, with the ground wire in excellent contact.

The CNC system prevents you from plugging and unplugging all of the cable plugs on the back of the chassis. The connection connecting the CNC system's rear output port must not be short-circuited with other power lines; otherwise, the CNC will be burnt. In a high-dust environment, the entire machine must be dustproof, and the dust must be cleaned on a regular basis to guarantee that the CNC system is clean. A committed person should be in charge of the CNC system, and the operator should be well educated. The AC/DC power supply utilized inside the CNC system cannot be connected to any other equipment.

Do not attempt to dismantle or change the system unless you are familiar with it. Perform regular maintenance and inspections on the system and machine tool every shift; execute secondary maintenance once a month, and perform primary maintenance every six months. At the time of ordering, the CNC system's settings should be adjusted strictly according to the instructions in this manual or the supplemental instructions; if the set parameters are beyond the specified range, the CNC system will function strangely or even be destroyed.

The system's LCD screen is delicate, and it should be covered while in operation. This system's technical specifications are subject to change without notice. That the system's USB port output power is relatively low, and it can only be utilized by the U disk. To avoid damage, it cannot be linked to other USB devices. Cutting machine SF-2100C-QG All types of flame/plasma, high-pressure water jet, and laser cutting machines may be utilized with the CNC system, which is extensively employed in metal processing, advertising, stone, and other sectors.

The system is extremely dependable, and it can withstand plasma interference, lightning strikes, and surges. During plasma processing, practical flame/plasma cutting process, automated corner rotation control, and height control; remote operation using the wireless remote control. It does kerf compensation and determines if the compensation in the software is appropriate, and it generates a report for the user to pick from.

Automated memory breakpoints, breakpoint recovery, and automatic power-off recovery. Arbitrary perforation point processing functions selection and selection. For thick plates, it has an epitaxial perforation function, and for thin plates, it has a bridging function. The user's control is considerably aided by back-off, selection, breakpoint recovery, optional perforation location, and other functions.Cutting can be transferred at any moment. It has a unique tiny line segment processing feature that makes it simple to walk and can be utilized in a variety of applications such as metal cutting and advertising, wrought iron, and so on. A collection of 24 visuals (which may be expanded and customized) including common basic machining components.

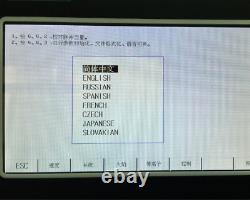

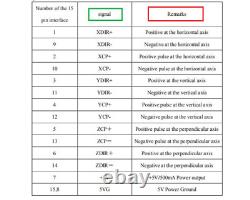

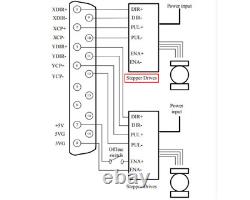

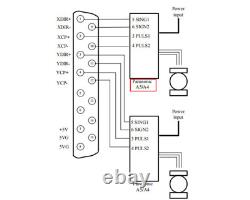

Compatible with StarCAM nesting software, as well as IBE (Germany), FASTCAM, and other popular nesting programs. Automatic monitoring of moving points, Chinese and English operating interface conversion, dynamic visual display, 1 to 8 times graphic magnification, U disk reading program, and fast software upgrade. Processor: ARM processor chip of industrial-grade. Color LCD panel with a 7-inch diagonal.16 optically isolated inputs and 16 optically isolated outputs are provided by the system. The number of linking axes is two (can be driven by X-axis bilaterally or Y-axis bilaterally). Minimum speed: 24 m/min; maximum speed: not less than 24 m/min.

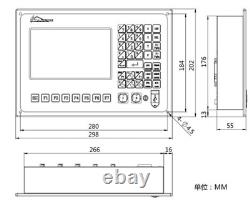

Flexible adjustability for the pulse equivalent. Processing methods are not limited; storage space: 4G big user program storage capacity. Dimensions of the chassis: 298 202 65 (mm). 0°C to +40°C working temperature; -40°C to +60°C storage temperature. Tool function (in this system is the flame width). When the arc is machined, the center coordinate value is reduced by the. Starting speed, adjustment time and maximum speed limit of each axis.Electronic gear ratio of each axis, machine origin, reference point, backlash, line offset, soft positive/negative limit. Ignition delay, preheating delay, cutting gun up/down delay, perforating torch up/down, piercing delay, etc. Cutting gun positioning delay, M command for arcing, M command for arc breaking, arc pressure detection selection, positioning detection selection, piercing delay. Flame/plasma selection, processing speed limit, edge perforation selection, metric/imperial selection, etc.

The parameters that have been changed are saved in the parameter area. Continuously press the S key to pick the external manual control button and determine if it is legitimate or invalid. Software upgrade operation instructions (software free upgrade). Format the USB flash drive in FAT or FAT32 format. It is recommended to use the FAT format.Copy the upgrade file into the USB flash drive. The name of the upgrade file must be STARTCNC. Press and hold the arrow button on the left side of the USB port to power on the system, power up the system, and plug the USB disk into the USB port of the system. The system automatically enters the upgrade interface, press the F1 button on the panel (ie, the corresponding button for the upgrade). If the upgrade is normal, after the upgrade is complete, the system will display Upgrade Successful!

Turn off the power, pull out the USB flash drive, and the upgrade process is complete. Second, the exception process of the upgrade process. Check that the name of the upgrade file must be STARTCNC. If this factor has been eliminated, you can re-operate according to the operation steps.

If multiple attempts still fail, you can call customer service. The details of the CNC system are as follows. 1pcs 25 core hole input plug (including sheath). 1pcs 25-pin needle output plug (with sheath).1pcs 15 core hole remote control plug (including sheath). 1pcs 15-pin pin motor plug (with sheath). 1pcs 9 core hole communication plug (including sheath). 1pcs 3P green terminal DC24V power plug. 1pcs Quick User Guide (Chinese).

Packing box size:length 400mm\width 220mm\height 340mm. SF-2100C outline installation dimension drawing: (unit: mm). Please check in image gallery. There are many options, including China Post.

We will try our best to help you! Dear buyers, if you are satisfied with our products, we can leave you 5-star feedback, we would be grateful. We will provide you with some excellent solutions. We promise to help you solve it asap, and make you feel satisfactory absolutely. Your recognition will make us more confident to develop business and serve you better.

What should I do if I don't receive my item? If the products have problems how to do it?Don't leave any bad reviews firstly, that cannot solve any problem. Factory sales, best quality, and competitive price! By the way, if you like our store, please add our store to your Favorite Stores, you can get our New arrival and Discount information in time. Due to the difference between different monitors, the picture may not reflect the actual color of the item. We guarantee the style is the same as shown in the pictures.

Please allow slight dimension difference due to different manual measurements. DEAR, IT'S NORMAL THERE IS COLOR SHADING. If you encounter any problems, broken, quality problems, please don't worry, and don't leave bad feedback.

We understand your mood, and will provide you with the best solution for your problem. Please give us the opportunity to solve the problem. In any case, please feel free to come to us, we are always here.Look forward to and thank you for your trust. SIGN UP FOR ALL THE LATEST NEWS AND EXCLUSIVE OFFERS. NEW ARRIVALS NOW AVAILABLE AT DISCOUNTED PRICES. Tedexports was initially developed by us in our specializing in manufacturing high-end accessories and items.

We are a Sri Lanka and China-based company with locations in Colombo and Beijing County as well as our new location It is also set to launch in California in the near future. We develop all of our products in-house and work alongside leading retail suppliers.

Our products can be seen and bought through hundreds of accessories dealerships, both privately and corporate-owned. You can enjoy top-quality product and high-quality services from us, trust we that you will have a pleasant shopping experience here.

We guaranty top quality with all of the products that we sell. We strive to be number one in the industry and are willing to beat our competitor's pricing as well as exceeding industry standards with respect to quality. This item is in the category "Business & Industrial\CNC, Metalworking & Manufacturing\Welding & Soldering Equipment\Welding Equipment & Accessories\Welders, Cutters & Torches\Plasma Cutters".

The seller is "tedexports" and is located in this country: CN. This item can be shipped worldwide.

- Item Type: Plasma Cutter

- Brand: Unbranded