24V THC HP105 Torch Height Controller for Arc Voltage CNC Plasma Cutting Machine

Designed Beeswax Machine Beeswax Embossing Machine Foundation Cell Size 4.9mm. 100ml Hydrothermal Autoclave Reactor with Teflon Chamber Vessel Kettle Synthesis. EPC-A12 Servo Edge Position Controller Stroke 150mm Web Guide Control System. GAA21750AK3 TT Elevator Debugger Lift Test Tool Unlock Blue Server + AVO Adapter. XYZ Axis 60MM60MM Manual Linear Stages Bearing Tuning Platform Sliding Table.

Fiber Optic Inspection Microscope 3.5 400X Video Fiber Inspection Probe APC+UPC. 200 300 500 Sieve Mesh-Electric Vibrating Sieve Machine Chinese Medicine.

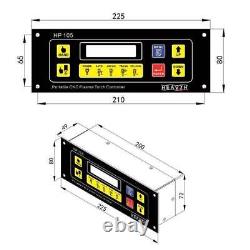

Torch Height Controller THC HP105 for Arc Voltage CNC Plasma Cutting Machine. Working voltage: DC24±10%, 50Hz/60Hz, Please prepare an isolated power, do not share with others such as an electronic valve. Especial Pay more attention the DC 24V. Lift motor: DC24V DC motor. Working temperature: Height controller -10?

HS style: Switch inspecting IHS suitable for all plasma. Both above-water and under-water cutting, Plasma Shield. Protector IHS suitable for above-water cutting's touch. Running transfer: Alternative Arc transfer and pierce transfer. Divided voltage ratio:100:1. Protection class: IP64, to prevent dust from entering. Installation connector: 2-pin, 4-pin, 5-pin, DB-9 core. Installation position: Keep away from heat, air convection good place. HP105 plasma torch height controller is equipped with constant current plasma. During cutting courses, the current always equals the given current. And the cutting arc voltage will be changed with the fixed speed being the height of torch changing. When the distance gets farther, the arc voltage increases; On the opposite, the arc voltage will decrease. HP105 plasma arc voltage height controller will inspect the voltage change, then control the distance between cutting torch and material via the lift motor. So that the arc voltage is fixed, the same is the height of cutting torch.Generally, the instruction will list all the cutting parameters for some type of plasma. The user can refer to these parameters. Adjust the voltage in the arc voltage height controller to match the selected current. The torch height will keep constant under regular speed.

In fact, the user should set the arc voltage according to the height of the cutting torch. In the status of automation, the arc voltage higher, then the height of the cutting torch higher.

LCD: display the working status and parameters. Manual: Auto / Manual mode selection increase, alternating work.

Arc test: standby press, arcing into the test mode. When arcing test, press to return to standby mode.

Menu: In standby, mode press to enter the parameter setting mode. When the parameter setting Press to return to standby. Confirmation: parameter setting mode, confirm that the set parameters.

Rise/fall: In standby mode, manual lifting torch. When parameter sets, subtraction parameter values. Torch Height Controller THC HP105.